TOWA's molding technology is used for manufacturing automotive electronic devices.

Product Case

Automotive Electronic Devices

TOWA's products and technolgy is used in various scenes of our everyday lives. This page introduces our molding technologies andequipment, which improves the reliability of ECUs and various automotive electronic devices.

- Resin sealing technologies that improve the reliability of ECUs and various automotive electronic devices

- Capable of sealing ECUs with stable quality

- Capable of handling large and high-density ECU packages with molding technologies that do not place a load on parts

Molding technology for enhancing the reliability of sensors and ECUs for automobiles

One of the important things in realizing a safe and comfortable environment as well as environmentally friendly automobiles is the reliability of electronic devices such as various sensors and ECU (Engine Control Unit).

Sensors and ECUs used in automobiles are constantly exposed to heat, vibration, water, oil and salinity. As a method of protecting electronic devices such as sensors and ECUs that are installed and used in harsh environments, sealing by resin molding instead of conventional casing and potting is available.

Ensuring Stable Quality with the Transfer Method

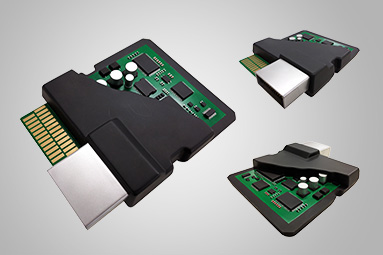

An example of a sealed ECU

The application of molding with the transfer method, which is an established method for semiconductor packages, enables the reliability of ECUs to be improved. The transfer method has been used for sealing semiconductors for a long time.

Reliability that is equivalent to that of semiconductor packages can be obtained by setting an ECU on a mold and covering and sealing it with a resin by pouring a melted thermosetting resin into it.

Equipment and technologies used for semiconductor packages can be applied as it is for this sealing process. In addition, sufficient knowledge of resins used for sealing has been obtained and accumulated through semiconductor packages. Accordingly, ECUs can be sealed with stable quality without conducting a new large-scale evaluation.

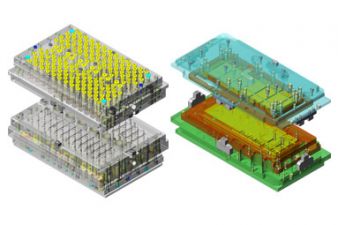

Applicable for ECU packages for larger size and higher density

In addition, if function is added to the ECU and it becomes bigger and uses a large amount of resin, compression molding can be used instead of the transfer method.

In the compression method, ECU can be appropriately ,molded by slowly and gently sinking the ECU after injecting the liquid resin into the mold. Also, the compression method is also effective when you do not want to apply large pressure or unnecessary load to delicate ECU built-in parts.

The compression method is TOWA's original method and we believe it will be useful for packaging ECUs that will become more advanced in the future.

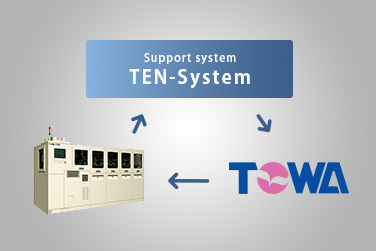

Related Technologies Owned by TOWA

Related Products

CPM-Series

The CPM-series molding equipment is capable of molding wafers and panels, which are growing larger, by utilizing the compression method.

PMC-Series

PMC is a series of equipment that enables high-quality molding by utilizing the compression method. Cumulative sales of these pieces of equipment have exceeded 400 units.

YPM-Series

The YPM-series molding equipment utilizes our world-leading transfer method.

From Kyoto to the World

From Kyoto to the World