TOWA's ultra precision element technology is utilized to manufacture high quality and high precision optical parts such as head up display.

Product Case

Head-up Display

TOWA's products and technologies are utilized in various scenes of our everyday lives. Here we introduce ultra precision element technologies that support the manufacturing of high quality and high precision optical parts used in head up displays.

- Assuming production process for optical component from designing to molding to achieve accuracy improvement and error reduction

- Maximizing the properties of products by addressing in the product design the problems that occur in each process of mold processing

- Considering the expansion and contraction caused by temperature changes during the ultra-precision electroforming (EF) processing in the post process

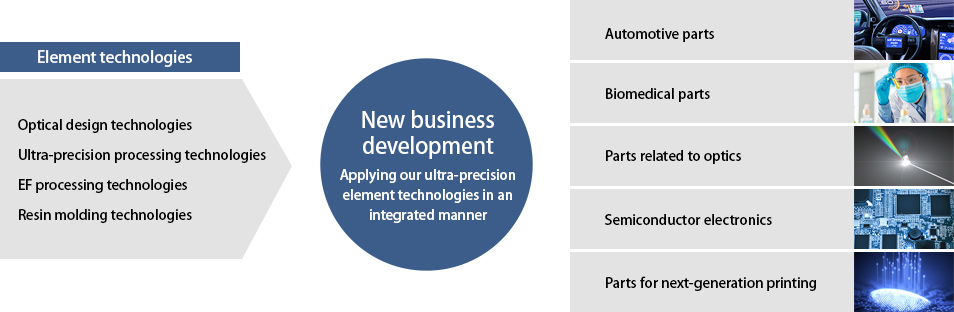

- Also applicable for automotive, bio-medical, optical and next-generation priting partsNot only for semiconductor and electoronical, inaddition to semiconductor and electronic parts

Consistent approach from designing to molding of optical parts requiring high quality and high accuracy

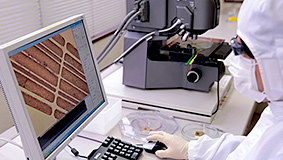

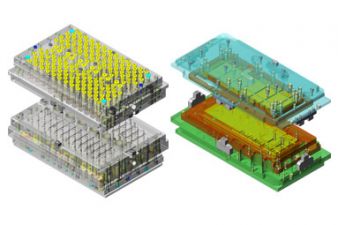

Manufacture of optical parts is divided into several processes such as design, mold making, resin molding. By dividing the process into divisions, we can conduct inspections at each stage and manufacture the ideal shape and performance at design time with high yield in final resin molding.

We handle the process of manufacturing optical components, from design to resin molding, in a consistent manner. By understanding and practicing all the processes involved in manufacturing optical parts, we can manufacture products maximizing the properties desired by customers.

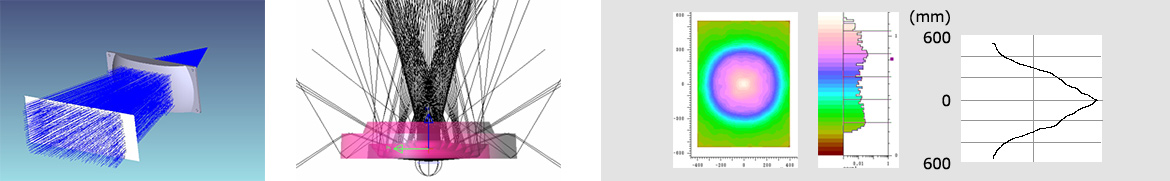

Use of Towa's Proprietary Optical Simulation System

We simulate the properties of optical parts by using our proprietary optical simulation system.

We also optimize their properties into those required by customers and suggest measures for reducing costs, based on our basic research on design to production, which we have undertaken for many years to manufacture high-performance products, as well as a wealth of material technologies, mold design technologies, and others.

Examples of simulation of optical properties

Technologies for Manufacturing Optical Parts that can be Applied Effectively in a Wide Range of Fields

We handle all the processes of optical parts manufacture -- that is, design, mold production, and molding -- in a consistent manner. We believe that our technologies can be applied for automotive parts, biomedical parts, parts related to optics, and parts for next-generation printing, in addition to semiconductors and electronic parts.

Related Technologies Owned by TOWA

Related Products

CPM-Series

The CPM-series molding equipment is capable of molding wafers and panels, which are growing larger, by utilizing the compression method.

PMC-Series

PMC is a series of equipment that enables high-quality molding by utilizing the compression method. Cumulative sales of these pieces of equipment have exceeded 400 units.

YPM-Series

The YPM-series molding equipment utilizes our world-leading transfer method.

From Kyoto to the World

From Kyoto to the World