At TOWA, we market molding equipment (resin sealing equipment) that utilizes the transfer method. With this method, a flowable resin for protecting the semiconductor chips is applied to the area around the semiconductor chip via a gate (supply port) before it is cured. In addition, we have also developed and market molding equipment that utilizes the compression method, whereby semiconductor chips are immersed in a flowable resin in advance and then the flowable resin is cured. Semiconductor manufacturers use larger lead frames and substrates in an attempt to improve productivity and reduce the production cost. In addition, semiconductor molding technologies are required to be compatible with the slimmer dimensions and higher integration of semiconductor devices and with increased thickness for compatibility with power devices and modularization. Our molding equipment caters to these various needs.

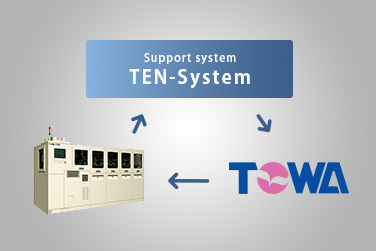

TEN-System

TEN-System supports TSS(Total Solution Service) comprehensively with IoT and a web system,allowing us to provide appropriate services promptly.

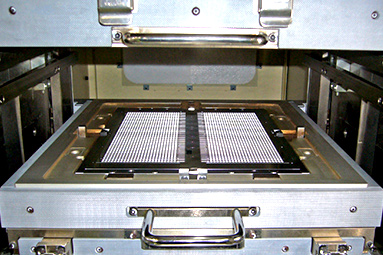

PMC2030-D

Compression Molding equipment PMC2030-D is released to meet growing demands for improvement of thickness accuracy by making products thinner. Improved package thickness accuracy, cleanliness inside machine, and productivity significantly.

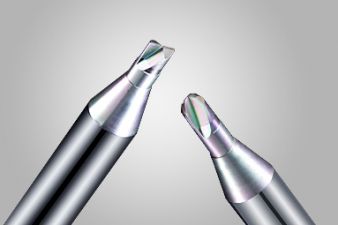

CBN End Mills with BANCERA

This is a new lineup that has joined the CBN end mill series. These tools boast an even longer life-span, which is enabled by Bancera, a new ceramic coating developed by TOWA.

Products

Molding Equipment

Singulation Equipment

Together with molding equipment, singulation system is one of the core equipments for the post process of semiconductor manufacturing. We develop dicers as a main function of singulation systems, thereby providing the optimal method of singulation for each type of manufactured product. In addition, our singulated product handlers contribute to improving customers' productivity with high throughput.

Ultra-Precision Molds

Ever since our establishment in 1979, we have been manufacturing ultra-precision molds by utilizing the module system, in which one ultra-precision mold is produced by combining divided parts. We have opened up a new era with this system.

The transfer mold in the multi-plunger design was born during this system evolution.

We have also developed the compression mold as a new molding process. We thus continue to provide leading-edge ultra-precision molds.

Tools, consumables

End Mill and Drill Series

Developed by utilizing technologies cultivated through the manufacture of ultra-precision molds, End mills and Drills from TOWA boast high precision, superior abrasion resistance, and a long life-span.

Mold Release Films

The T-series mold release films from TOWA are release films optimized for molding equipment.

From Kyoto to the World

From Kyoto to the World