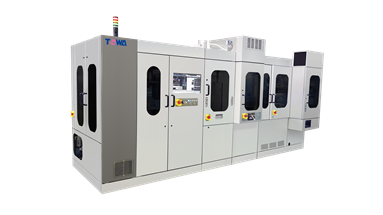

PMC-Series

The ultimate compression molding system pursuing market needs

Features

- Applicable for 100×300 mm workpiece size.

- High-accuracy press improves package thickness accuracy.

- Improve productivity by making UPH higher.

- Both Granular and Liquid type resin are available in 1 system.

- Modular concept to adapt to different production quantities.

Compression molding system for heat sink/metal shield applications

Features

- Compression molding for exposed Heat sink / Metal shield applications.

- Heat sink / Metal shield exposure and molding combined in one process.

- Simple conversion to mold conventional product types.

- Modular concept to adapt to different production quantities.

Compression Molding Equipment

Features

- Advanced high accuracy press improves package thickness accuracy

- High precision molding at ultra low pressure enables high quality molding for microstructured devices

- Single-layer structure

- Both granular and liquid resin are available in 1 system

- Compatible with large 100mm X 300mm workpieces

- For inquiries about products, click here.

Compression molding system for high quality and low cost production

Features

- The compression molding system which pioneered TOWA's molding technology.

- Applicable for 100×300 mm workpiece size.

- Original Cavity Down Structure enables stable molding with high quality.

- Modular concept to adapt to different production quantities.

Compression molding system for heat sink/metal shield applications

Features

- Compression molding for exposed Heat sink/Metal shield applications.

- Heat sink/Metal shield exposure and molding combined in one process.

- Simple conversion to mold conventional product types.

- Modular concept to adapt to different production quantities.

Compression Molding Equipment

Features

- Integration of TOWA's proprietary compression technologies with a modular method

- Press mechanism with a hold frame structure

- Single-layer structure

- Capable of molding large frames/substrates in bulk

- Optimal for preventing wire flow of long wires

- Compatible with large 100mm X 300mm workpieces

- Higher effective utilization ratio of resins

- Smaller footprint

- Improves the investment efficiency of the user (improvement of COO)

- Environmentally friendly equipment that generates no waste

- For inquiries about products, click here.

Relevant Products/Services

Product Case

-

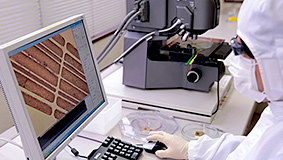

Introduce our manfufacturing technology used for finger print sensors.

-

Introduce ultra precision element technologies that support the manufacturing of high quality and high precision optical parts used in head up displays.

-

Introduces our molding technologies andequipment, which improves the reliability of ECUs and various automotive electronic devices.

-

Introducing the floating image lens and various application examples based on our ultra-precision mold processing technology, EF technology, and injection molding technology.

From Kyoto to the World

From Kyoto to the World