FMS-Series

FMS4040

FMS4040

Singulation system to reduce manpower

Features

- Wide variety of package offloading methods.

- Automatic blade exchange and dressing operations reduces necessary time by 50% leading to increased productivity.

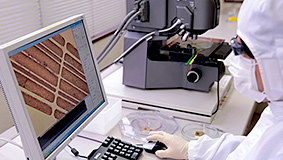

- Vision unit with auto-focus function improves inspection accuracy and work efficiency.

- Abundant options that contribute to high quality, stable production, and SDGs.

- For inquiries about products, click here.

FMS3040 Tray offload type

FMS3040 Ring offload type

Singulation system for cutting various packages

Features

- Wide variety of package offloading method.

- Applicable for 100×300 mm workpiece size.

- Capable of minimum cutting size of 1.0×1.0 mm.

- Achieved UPH 40,000 by high speed handling.

Singulation Equipment

Features

- Full auto machine for work up to 100mm X 300mm

- Various package offload methods available

- Compatible for small packages (Minimum 1.0mm X 1.0mm)

- Single table, twin dicer specification

- High speed loading enables UPH of 27,000

- Can singulate packages with large warpages by warpage straightening

- Compensation of package offset, optimization of cutting accuracy

Singulation system for cutting substrates

Features

- Supports large-sized substrates.

- Fully automatic from cutting to washing/drying and visual inspection.

- Achieving high-precision cutting with optimal jig dicers and handlers that meet customer needs.

- Visual inspection function equipped as standard. Supports substrate thickness autofocus.

Half-cut machine suitable for wettable QFN packages

Features

- Enables high-precision blade cutting of lead-less device products such as QFN packages.

- Selectable blade cut(FMS3040-HC) or laser cut(LGR1040) depending on process and lead frame design.

- Improvement of half-cut depth accuracy using a warping correction pressing mechanism.

- For inquiries about products, click here.

Relevant Products/Services

Product Case

-

Introduce our manfufacturing technology used for finger print sensors.

-

Introduce ultra precision element technologies that support the manufacturing of high quality and high precision optical parts used in head up displays.

-

Introduces our molding technologies andequipment, which improves the reliability of ECUs and various automotive electronic devices.

-

Introducing the floating image lens and various application examples based on our ultra-precision mold processing technology, EF technology, and injection molding technology.

From Kyoto to the World

From Kyoto to the World