As the leading company in resin sealing technologies for semiconductors and other electronic components, we at TOWA Corporation have supplied

a number of ultra-precision molds to the market.

These products have been highly acclaimed by customers.

As the leading company in resin sealing technologies for semiconductors and other electronic components, we at TOWA Corporation have supplied

a number of ultra-precision molds to the market.

These products have been highly acclaimed by customers.

Ever since our establishment in 1979, we have been manufacturing ultra-precision molds by utilizing the module system, in which one ultra-precision mold is produced by combining divided parts. We have opened up a new era with this system.

The transfer mold in the multi-plunger design was born during this system evolution.

We have also developed the compression mold as a new molding process. We thus continue to provide leading-edge ultra-precision molds.

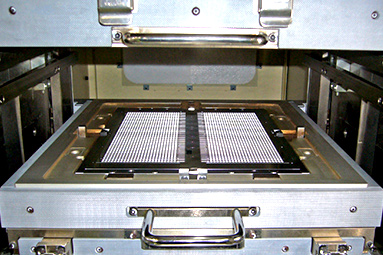

Transfer molds in the multi-plunger design

Transfer molds in the multi-plunger design feature multiple resin-feeding pots, which significantly increases the effective utilization ratio of resin, reduces the molding cycle, and dramatically improves the molding quality.

We meet the customers' demands for complicated, high-precision packages with our proprietary ultra-precision processing technologies.

We also boast highly reliable quality evaluations of molds and products, which are enabled by the latest measuring devices.

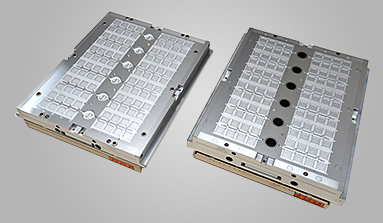

Compression Molds

We have dramatically improved our resin sealing technologies by developing compression molds following transfer molds in the multi-plunger design.

Compression molds manufactured with our ultra-precision processing technologies provide high-precision, high-quality products by minimizing damage in the molding of low-k materials, thinning wires, and even large substrates and wafers.

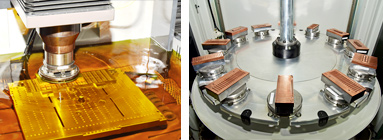

Our manufacturing plant has a large number of unique CNC machines for realizing ultra-precision processing.

We have built the world's most advanced production line that manufactures high-precision molds with stable quality by introducing an automated production system, a continuous unmanned operation system compatible with high-mix low-volume production, and our proprietary manufacturing system with artificial intelligence system (AIS), which are linked with CAD/CAM.

These ultra-precision processing technologies have begun to be applied in a wide variety of fields as listed below, rather than being used solely for semiconductors.

World's most advanced production line with ultra-precision processing

Electric discharge machine that is capable of micron-level processing (left) and palette changer (right)

Introduce our manfufacturing technology used for finger print sensors.

Introduce ultra precision element technologies that support the manufacturing of high quality and high precision optical parts used in head up displays.

Introduces our molding technologies andequipment, which improves the reliability of ECUs and various automotive electronic devices.

Introducing the floating image lens and various application examples based on our ultra-precision mold processing technology, EF technology, and injection molding technology.