TOWA's coating technology features superior durability and mold releasability

Our Commitment to Technologies

Coating Technology

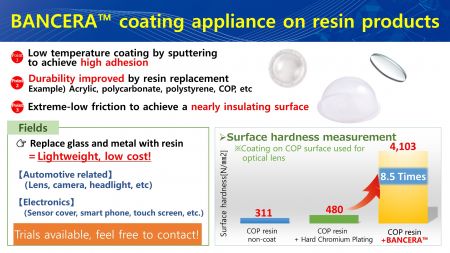

Bancera coating, which is our proprietary coating technology, is a coating technology that greatly improves the durability, releasability and antifouling properties of molds as compared with conventional coatings. It has been used not only for mold chases but also in a wide range of fields including pharmaceutica tableting machines, machine sliding parts of equipment, surface treatment to glass and the like.

What is Bancera Coating

By controlling the crystal structure of the coating surface at the atomic / nano level, it is an unrivaled high performance coating technology that combines excellent releasability and antifouling properties. The surface layer part of Bancera coating is composed of stable rare earth oxide ceramic and it is characterized by high safety compared with conventional coating and it can be expected to be applied to a wide range of applications. It does not include corrosive halogens such as chlorine and fluorine, alkali metals and alkaline earth metals such as sodium (Na), potassium (K), calcium (Ca), radioactive elements and RoHS directive hazardous substances.

Excellent surface treatment properties applicable to multiple fields

As molds greatly affect the appearance and quality of products, abrasion resistance and surface treatment are important as well as materials.

Our Bancera coating is a new coating technology which greatly enhances releasability and antifouling properties and has superior surface treatment characteristics than conventional coatings.

Abrasion resistance

Compared with hard chrome coating 1050 HV, Bansera has 2440 HV and surface hardness is more than twice higher, and it is excellent in abrasion resistance.

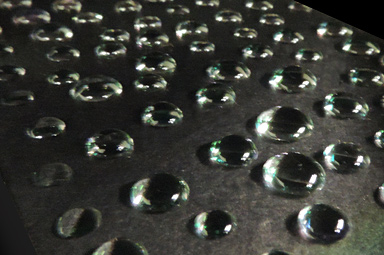

Antifouling property

Bancera has high water repellency with a water contact angle of 96 to 105 degrees and is excellent in antifouling properties.

Releasablity

The mold release force from the mold can be reduced by 60% compared to conventional hard chrome coating.

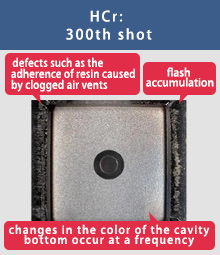

With conventional hard chrome coating, defects such as airvent clogging due to adhesion of resin, depostion of flash, discloartion in the bottom of the mold, could be observed after 300 shots. With Bancera coated molds, defects were not observed even after 1,000 shots.

Due to the superior durability, releasability and antifouling property of Bancera, it is possible to reduce the frequency of cleaning to one eighth. Not only can we ensure product quality, but we can contribute to the improvement in the maintainability of the mold tool.

Application to other fields

Bancera coatings are beginning to be used in various fields due to their high functionality and safety. In addition semiconductor mold chases and injection mold chases, it is now being such areas as tablet molding for pharmaceuticals, countermeasures against sliding parts of mechanical parts, surface treatment of tempered glass. Bancera has earned high praise from customers in diverse industries.

| Features of Bancera Coating | |

|---|---|

| Color | Interference color |

| Thickness | 2.8 to 3.2μm |

| Surface hardness | 2,440HV |

| Surface roughness | 0.01μmRa / 0.05μmRz |

| Water contact angle | 96 to 105° |

| Electrical conductivity | No |

| Treatment temperature | 400 to 450 °C |

| Effective coating volume* |

1) 320mm x 114mm x t30mm |

*The effective coating volume can differ according to the thickness of the object.

Product List

-

TOWA is a leading company in the semiconductor molding equipment market. We offer equipment using our proven transfer molding method, and high quality / flow free compression molding method.

-

With our expertise in the field of singulation, high speed handling and image analysis technology, we offer high quality singulation equipment.

-

As the leading company in resin sealing technologies for semiconductors and other electronic components, we at TOWA Corporation have supplied a number of ultra-precision molds to the market. These products have been highly acclaimed by customers.

-

Developed by utilizing technologies cultivated through the manufacture of ultra-precision molds, End mills and Drills from TOWA boast high precision, superior abrasion resistance, and a long life-span.

From Kyoto to the World

From Kyoto to the World