EF process technology for duplicating molds with high precision

Our Commitment to Technologies

EF (Ultra-Precision Electroforming) Process Technology

EF (ultra-precision electroforming) process technology is effective for the mass production of molds that require complicated shapes and high precision. Using the same electrochemical reaction used in electroplating, EF process technology enables ultra-precision molds to be duplicated and produced within around 24 hours, while it takes 700 hours using the machining process. This greatly improves productivity and reduces cost.

- Nano-level control using our proprietary technologies

- The technology ensures both high precision and high durability

- Compatible with a range of metal materials in addition to nickel

- Capable of duplicating a master with diameter of up to 240mm

Mass-producing molds for products requiring high-precision processing technologies within a short period of time and at a low cost

What is EF?

EF (Ultra-Precision Electroforming) process technology uses the same electrochemical reaction used in electroplating. It reproduces the shape of the master with high precision by electrodepositing metallic ions, which are decomposed by an electric current, on the surface of the master. EF process technology boasts superior transferability and reproduces the shape of the master with high dimensional precision.

In addition, our EF process enables the production of thicker products than conventional technologies by controlling the stress generated during the process. This not only permits the high-precision, accurate reproduction of the master but also ensures the high durability of the reproduced molds.

Mass-producing molds for products requiring high-precision processing technologies within a short period of time and at a low cost

EF (ultra-precision electroforming) process technology is effective for the mass production of molds that require high precision in addition to a complicated shape. EF process technology enables the mass-production of molds from one high-precision master in a single processing step, greatly improving productivity and reducing costs.

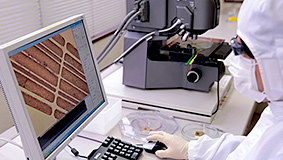

At TOWA we have a dedicated clean room for EF process, under thorough control, we are able to mass produce high precision molds efficiently in a short period of time.

Compatible to not only nickel, but nickel alloy.

Pure nickel is used in general EF processing, but our company can change the characteristics of the material to be electrodeposited according to the purpose of the mold tool.

By changing not only pure nickel but other metal materials, heat resistance can be improved or material properties can be changed. By EF processing with harder alloy or changing the material properties, a more durable mold tool can be manufactured.

Capable of Duplicating a Master with a Diameter of up to 1,000mm

Our EF (Ultra-Precision Electroforming) process enables the duplication of a master with a diameter of up to 1,000mm. A combination of this EF process technology with our ultra-precision, microfabrication technology enables the mass-production of molds for products requiring high-precision processing technologies. Micro lens arrays used for head-up displays etc., can be mass produced in a short time at low cost.

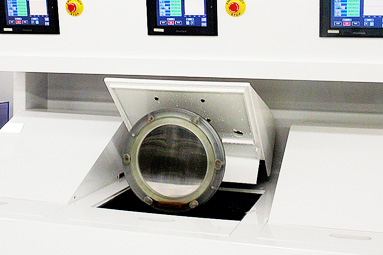

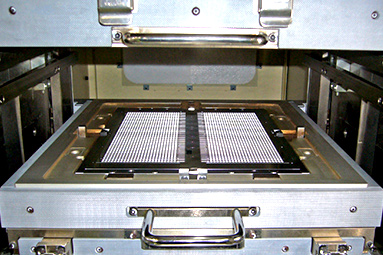

EF (Ultra-Precision Electroforming) equipment

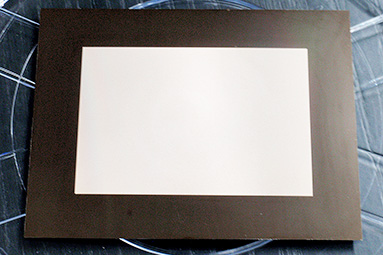

Micro lens array made using the EF process

Product List

-

TOWA is a leading company in the semiconductor molding equipment market. We offer equipment using our proven transfer molding method, and high quality / flow free compression molding method.

-

With our expertise in the field of singulation, high speed handling and image analysis technology, we offer high quality singulation equipment.

-

As the leading company in resin sealing technologies for semiconductors and other electronic components, we at TOWA Corporation have supplied a number of ultra-precision molds to the market. These products have been highly acclaimed by customers.

-

Developed by utilizing technologies cultivated through the manufacture of ultra-precision molds, End mills and Drills from TOWA boast high precision, superior abrasion resistance, and a long life-span.

From Kyoto to the World

From Kyoto to the World