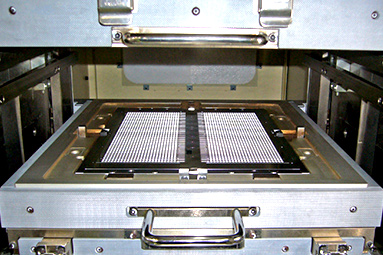

The press module has been optimized through continuous simulations and actual machine verifications.

Our Commitment to Technologies

Press Design Technologies

We have been developing, manufacturing and selling semiconductor manufacturing equipment for many years. By taking advantage of our extensive track record, we design press modules in a manner that optimizes the shape of every single component part.

Structural Analysis of the Condition of Components based on Mold Data

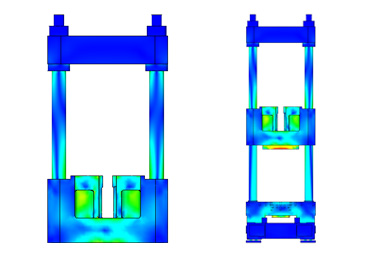

Visualization of pressure distribution on the press module through simulation using 3D CAD data

In developing or improving press modules, we check the following points by conducting simulations based on 3D CAD data to ensure the optimal quality of the press modules.

- Whether pressure is applied evenly to the entire mold

- The type of stress applied to the components of the press

To provide an example of the analysis, we modify the shape of the components of a press module based on data from internally manufactured molds and check for the resulting changes. We do this because the pressure distribution on a mold changes according to the condition of the components to which pressure is being applied, thereby influencing the flatness of the product to be molded. In semiconductor encapsulation and resin molding, pressure needs to be applied evenly to the entire matching surface of the upper and lower molds.

Further, the condition of the components during the application of pressure also influences the durability of the press module. It is also necessary for the installation area to be as small as possible. This makes it necessary to consider the shape of every single component of the press module when designing it.

We maintain the high quality of the presses we design by undertaking a series of simulations and reflecting the results of the simulations in the design before testing the prototype and mass-produced presses.

Providing Higher Precision Semiconductor Encapsulation

We ensure the high-quality molding of our press modules by not only utilizing press design technologies, but also by combining them with automation technologies, mold technologies, and control technologies.

By owning all of these technologies, we are able to provide optimal solutions in the future panel and wafer level encapsulation for which high precision is required.

Product List

-

TOWA is a leading company in the semiconductor molding equipment market. We offer equipment using our proven transfer molding method, and high quality / flow free compression molding method.

-

With our expertise in the field of singulation, high speed handling and image analysis technology, we offer high quality singulation equipment.

-

As the leading company in resin sealing technologies for semiconductors and other electronic components, we at TOWA Corporation have supplied a number of ultra-precision molds to the market. These products have been highly acclaimed by customers.

-

Developed by utilizing technologies cultivated through the manufacture of ultra-precision molds, End mills and Drills from TOWA boast high precision, superior abrasion resistance, and a long life-span.

From Kyoto to the World

From Kyoto to the World